Understanding the Complexities of Eddy Current Testing

Nondestructive testing (NDT) encompasses a variety of methodologies used to evaluate the properties and integrity of materials, components, or structures without affecting the future usefulness of the material or component being tested. NDT is divided into several broad methods such as Radiographic Testing (RT), Ultrasonic Testing (UT), and Electromagnetic Testing (ET). Each method is further subdivided into more specific applications called techniques. One such technique of the ET method is Eddy Current Testing (ECT), which uses swirling electric currents called “eddy currents” to detect surface and near-surface defects in thin conductive materials. ECT is widely used in industries like aerospace, power generation, automotive, and manufacturing to assess the condition of critical components, ensuring safety and equipment reliability.

Initially, both managers and engineers were skeptical of Eddy Current Testing, viewing it as abstract and difficult to trust compared to more traditional methods, such as Radiography or Visual Testing (VT). To this day, Eddy Current Testing is often jokingly referred to as “black magic” by those who do not understand the physics of electromagnetic induction and test coil impedance. However, once industry leaders began to understand the capabilities of ECT, the 1970s ushered in an almost explosive expansion of test applications across various industries. Two industry sectors that quickly realized the benefits of ECT were aerospace and nuclear. Much of what industry had learned about ECT is due to extensive research conducted at national test labs in the 1950s and 60s. Two such labs are the Oak Ridge National Laboratory (ORNL) in Tennessee, and Hanford’s Engineering Development Laboratory in Washington state (there are several other such labs across the USA and Canada). As industries adopted ECT, its applications expanded rapidly, proving its effectiveness in ensuring structural integrity and reliability across a variety of sectors.

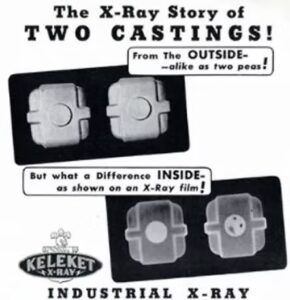

Eddy Current Testing is a powerful and advanced method of non-destructive testing, but it’s also one of the most misunderstood by those often affected by its test results. For many stakeholders, the challenge lies in understanding the technology behind ECT and trusting its results when compared to more visually intuitive methods like radiography or liquid penetrant testing. The abstract nature of ECT’s data can make it psychologically difficult for decision-makers to embrace—especially when decisions are based on data that is indecipherable to the untrained. For example, take a look at the following radiography advertisement from 1943:

The pictures above tell an amazing story. At the top are shown two castings, both from the same mold apparently identical and both acceptable based upon the lack of surface imperfections.

However, X-Ray inspection shows that one is free from defects and practically perfect, but the other shows gas pockets which should mean immediate rejection. Thus, X-ray inspection saves costly machining as well as the probability of an expensive break-down in use.

Similar to x-ray radiographs, other NDT methods such as Liquid Penetrant Testing (PT) and Magnetic Particle Testing (MT) produce images where even the most novice observer can view the results and make sense of what they see.

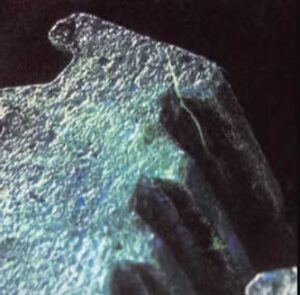

Liquid Penetrant Testing (PT)

Magnetic Particle Testing (MT)

Breaking the Psychological Barrier to ECT

Despite its benefits, Eddy Current Testing is often met with skepticism by those unfamiliar with its principles. This article serves to break down these psychological barriers by offering straightforward, practical explanations and support for interpreting results, so management can make informed, confident decisions.

Building Trust in Eddy Current Testing Results

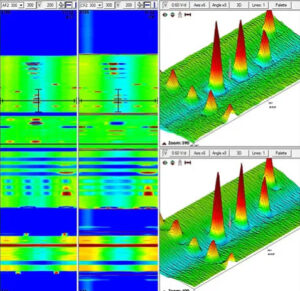

Untrained observers of eddy current signals often struggle to accept Eddy Current Testing because it challenges traditional notions of defect detection. Instead of a visible flaw, ECT provides a continuous flow of impedance vectors and phase angles that require expert interpretation. However, with automated analysis and advanced software, results can now be presented in more intuitive and transparent formats, providing management with confidence in ECT’s findings without the psychological hurdle of trusting complex signal patterns that seem abstract or unrelatable.

ECT vs. Traditional NDT Methods: Why the Challenge

Compared to NDT methods such as liquid penetrant or visual testing, Eddy Current Testing often seems more abstract. Engineers, executives, planners, and project managers may find it more easy to accept visible, tangible results. However, what ECT lacks in visual simplicity, it more than compensates for in precision, making it the ideal choice for detecting small, critical flaws in materials such as the thin aluminum skin on an aircraft, or heat exchanger tubing in a nuclear power plant. Overcoming the initial hesitation comes down to understanding that while ECT requires interpretation, its results are consistently reliable when qualified data evaluation techniques are used.

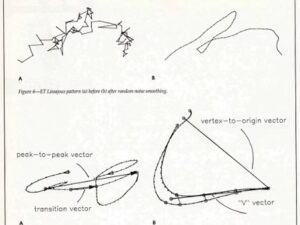

Interpreting the “Squiggly Lines”: Trusting the Experts in Eddy Current Testing

To the untrained eye, the squiggly lines on an eddy current display may seem confusing or even indecipherable. However, eddy current analysts undergo extensive training to accurately interpret the signals and identify subtle patterns within the data. These analysts are adept at recognizing material properties, differentiating between harmless anomalies and critical defects, and understanding how variables like conductivity, permeability, and probe configurations affect the readings. For example, an experienced data analyst can differentiate between a shallow surface crack and slight changes in material thickness even though the two material properties may provide nearly identical signals. Eddy current data is evaluated by observing variations in signal phase and amplitude, often using multiple test frequencies.

Because of this high level of expertise and the rigorous logic used in interpreting the data, eddy current testing results can be relied upon to provide accurate insights into the integrity of materials and components. The logical processes behind these analyses are so solid that computer systems can be “trained” to analyze the data as well. In fact, automated analysis systems have been used for decades in some industries, and today they are commonly applied to process large volumes of eddy current data quickly and efficiently.

As artificial intelligence becomes more prevalent, its use—along with automated analysis in general—does not replace human data analysts. Instead, it takes over the tedious and voluminous data screening tasks, freeing analysts to focus on critical decision-making and higher-level evaluations.

Looking ahead, the integration of artificial intelligence into Eddy Current Testing will revolutionize the field by enabling real-time data analysis, predictive maintenance, and enhanced defect detection capabilities. AI algorithms can learn from vast amounts of ECT data to identify patterns and anomalies that might be missed by human analysts, leading to more accurate assessments and proactive interventions. This advancement will not only improve the efficiency and reliability of ECT but also help industries prevent failures before they occur, ultimately ensuring higher safety standards and cost savings. As eddy current testing continues to evolve, embracing these advanced technologies becomes essential for industries committed to safety and efficiency. By overcoming psychological barriers and trusting in both expert analysis and automation, we can ensure the highest standards of material integrity.