Probes

Our attention is directed to the development of probes

There are national and international standards as well as guidelines by manufacturers and operators that specify minimum requirements for inspection systems used for many applications. This is why our attention is directed to the development and manufacture of probes and probe systems.

We react to customer requirements and

fall back on our wealth of know-how

We are able to quickly and flexibly respond to the customers’ requirements with a multitude of probe types. If a special probe has to be developed for a particular inspection we can fall back on a wealth of know-how.

Please download our Eddy Current Sensor Catalogue for more Information.

Scanners

Absolute probes, differential and multi differential probes Dynamic testing for minute defects with high local resolution and great sensitivity, carried out almost independently of the feed speed. At the same time, the highly developed filtering technology in our test systems is employed to the full and most interfering effects can be suppressed. We have the appropriate system for all investigations of plane surfaces, small and largeholes, pipe interiors and exteriors, ranging from 0.8 mm to 200 mm.

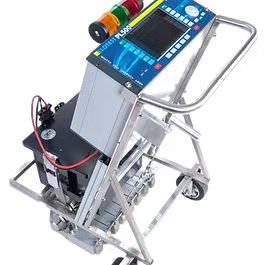

Elorail

The ROHMANN-inspection trolley is made from ultra-lightweight carbon fiber and is easily handled by just one operator. The trolley can be assembled and disassembled without tools within a matter of minutes. It is versatile and may be equipped with a variety of eddy-current test instruments depending on the inspection at hand. It is guided with a new and patented magnetic holder that enables an extremely smooth running and precise inspection of the entire rail head. The trolley is solely guided along the running edge by magnetic force (adjustable) and is completely suitable for switches.

Elowheel

Eddy Current Aircraft Wheel Inspection System optimized for:

• Surface inspection

• Inspection for hidden cracks

• Conductivity measurement

• Bore hole inspection

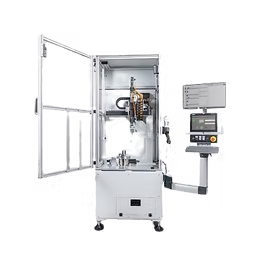

Eloscan

The EloScan-system has been designed mainly for the eddy-current inspection of rotationally symmetrical components of aircraft engines. Due to its very universal design the system is also able to scan complex geometries that require very precise probe guidance and a high repeating accuracy.

Elotest PL650

Flexible and precise 3-axis eddy current testing for cracks and grinding burn. The Flexitest is suitable for flexible testing of individual parts and pre-series products as well as for repeated testing of series components.

Elotest IS3

Single channel eddy current test instrument for automated testing tasks. The single channel test instrument, designed with protection class IP54, can be integrated directly into the production process, for example for automatic screw testing machines. It can be integrated into existing systems with minimal expenditure. With a frequency range from 10 Hz to 12 MHz, a universal signal filter and I/O interface, this test instrument is an efficient alternative for fast crack detection and sorting tasks.

Elotest HST

During steel production, increased local hardening may occasionally occur on the surfaces of semi-finished products.

In the further processing and later use of the finished products, this hardening (also called hard spots) can cause problems or lead to component failure. Because of this, relevant specifications increasingly call for surface hardness testing. Testing was previously only possible using “destructive“ methods (Vickers, Brinell, Rockwell) on samples or, non-destructively, using the Leeb rebound hardness test.

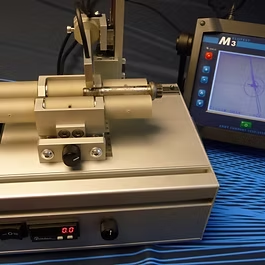

Elotest M3

The new ELOTEST M3 is based on the small and powerful ELOTEST M2, well known as the smallest handheld eddy current tester on the market. The ELOTEST M3 offers a large size LCD display with stunning definition and brightness. When multiple inspectors have to review images for evaluation or precise handling of the probe does not allow capability of holding the instrument, the M3 will be the instrument of choice based on the large display and intuitiveness of the parameter adjustments.

Elotest M6

With the ELOTEST M6 you have the most innovative handheld tester in its class in your hands. Whether in a horizontal orientation as a tabletop or vertically as a handheld tester – all flexibility in one device. Whether right-handed or left-handed, all personal habits of the user are taken into account.

The 7″ touchscreen gives you a comprehensive and flexible overview of your test result. With the 3-fold Multi-Touch, you have your finger on the pulse and the test device can be operated in any situation.

Always with you: reference standards directly on the test device. Depending on the test requirements, the reference parts can be exchanged individually.

Elotest B300

As the successor of the ELOTEST B1 the ELOTEST B300 opens new future-oriented dimensions. The B1’s proven eddy-current technology and the latest software and hardware components have been combined into a powerful instrument that may be used with or without an external computer. Additional software (e. g. ScanAlyzer) further expands the already excellent features of the B300.

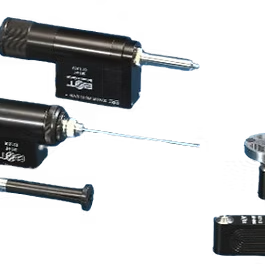

Elotest M2V3

The ELOTEST M2 is a universal one-hand test instrument for surfaces, bore holes and hidden structures. In addition, it measures the conductivity and layer thickness of all materials. The ELOTEST M2 features a DUAL-frequency inspection with mix and covers the entire frequency range from 10Hz to 12MHz. It offers all filter functions (LP, HP, BP) to optimize signals for static and dynamic inspections. The crisp LCD with LED-backlight that works even in direct sunlight ensures an optimum display of the test signals. Integrated reference standards make the on-site work easier and faster.

Rohmann Control 2023

Many thanks to all our visitors at the Control trade fair in Stuttgart. It was a successful event where we were able to present our new products. We look forward to seeing you in 2024! Until then, here are a few impressions as a reminder. #control #rohmanngmbh #eddycurrent #M6 #PL650 #qualityassurance #qualitätsmanagement

EloScan mit ScanAlyzer

Das EloScan-System mit seiner präzisen Sensorführung ist für die Wirbelstromprüfung rotationssymmetrischer Triebwerkskomponenten sowie für komplexe Geometrien konzipiert. Unsere Prüfsysteme erfüllen und übertreffen viele technischen Prüfanforderungen zur automatisierten Prüfung von Triebwerkbauteilen diverser Triebwerkhersteller. Der Multiachs-Industrieroboter arbeitet mit einem Rohmann-Wirbelstromprüfgerät und angepasster ScanAlyzer-Software gemäß diverser Prüfanweisungen.

N-Dect Flexitest mini

Discover the Flexitest advanced family – eddy current testing machines with precise 3-axis interpolation for your crack and grinding burn tests. Equipped with the ELOTEST PL650 RC eddy current tester from Rohmann GmbH. Eddy current testing technology – excellent signal-to-noise ratio thanks to integration of the latest high-performance testing technology.

Rohmann GmbH – wire & tube 2022

Endlich wieder Präsenz zeigen. Rohmann GmbH auf der Messe wire & tube in Düsseldorf. Finally showing presence again. Rohmann GmbH at the wire & tube trade fair in Düsseldorf, Germany.

ELOTEST PL600

Zur Prüfung des Härteverlaufs an Wellen. Die Toleranzbandschwelle nutzt wegbasierte Wirbelstromsignale. Es sind zwei Arten von Toleranzbandschwellen verfügbar: • Toleranzband Y-d (wegbasierte Amplitude der vertikalen Signalkomponente) und • Toleranzband X-d (wegbasierte Amplitude der horizontalen Signalkomponente).

Eddy Current Sorting

Eddy Current Sorting of small components for hardness, material differences with encircling coil.

Eddy Current Edge Inspection with Video Endoscope

Eddy Current Edge Inspection with Video Endoscope on turbine blades of aircraft engines through a maintenace hole with a diameter 8 to 10 mm.

Conductivity Measurement

Conductivity Measurement of non-ferromagnetic materials between 1 % IACS and 110 % IACS as well as coating thickness measurement of non-conductive layers on conductive but non-ferromagnetic base material.